When selecting the terminal harness processing factory, we attach great importance to each process of harness processing. Because the fineness of the process is directly related to the quality of the harness. Therefore, for a good wire harness enterprise, the wire harness processing process should be meticulous, and strict management should be used to ensure good quality. Wire harness processing network is a domestic enterprise specializing in the production of medium and advanced complex wire harness products. Harness production mainly includes the following processes:

1. Incoming material acceptance:Use ROHS instrument to conduct environmental test and check whether the quantity of incoming materials required for all harnesses meets ROHS standards. Required equipment: OHS test equipment. Processing requirements: incoming materials shall not contain harmful substances such as lead, mercury, cadmium and brominated biphenyls.

2. Wire delivery equipment:Place the wire to be processed on the transmission line frame. Required equipment: wire feed frame. Technical requirements: pay attention not to scratch the wire surface with scratches.

3. Transmission line:Place the wire on the wire feeder. Necessary equipment: wire feeder. Technical requirements: pay attention not to scratch the wire surface by scratch.

4. Cutting:Cut the required length of wire with the cutting machine. Equipment required: computer cutting machine. Technical requirements: it is not allowed to cut the wire surface; Cutting copper wire is not allowed; The stripping length shall not exceed ± 1mm.

5. Offline:Offline: take off the insulating jacket of the corresponding length of wire at the connection and strip it according to the SOP requirements. Necessary equipment: pneumatic peeling machine. Technical requirements: the surface shall not be crushed, the length shall not exceed ± 1mm, and the stripping length shall not exceed.

6. Twisting:Route the wire twist at the connector. Necessary equipment: twisting machine. Technical requirements: it is not allowed to scratch the wire surface; The copper wire must be tightened without loose wires.

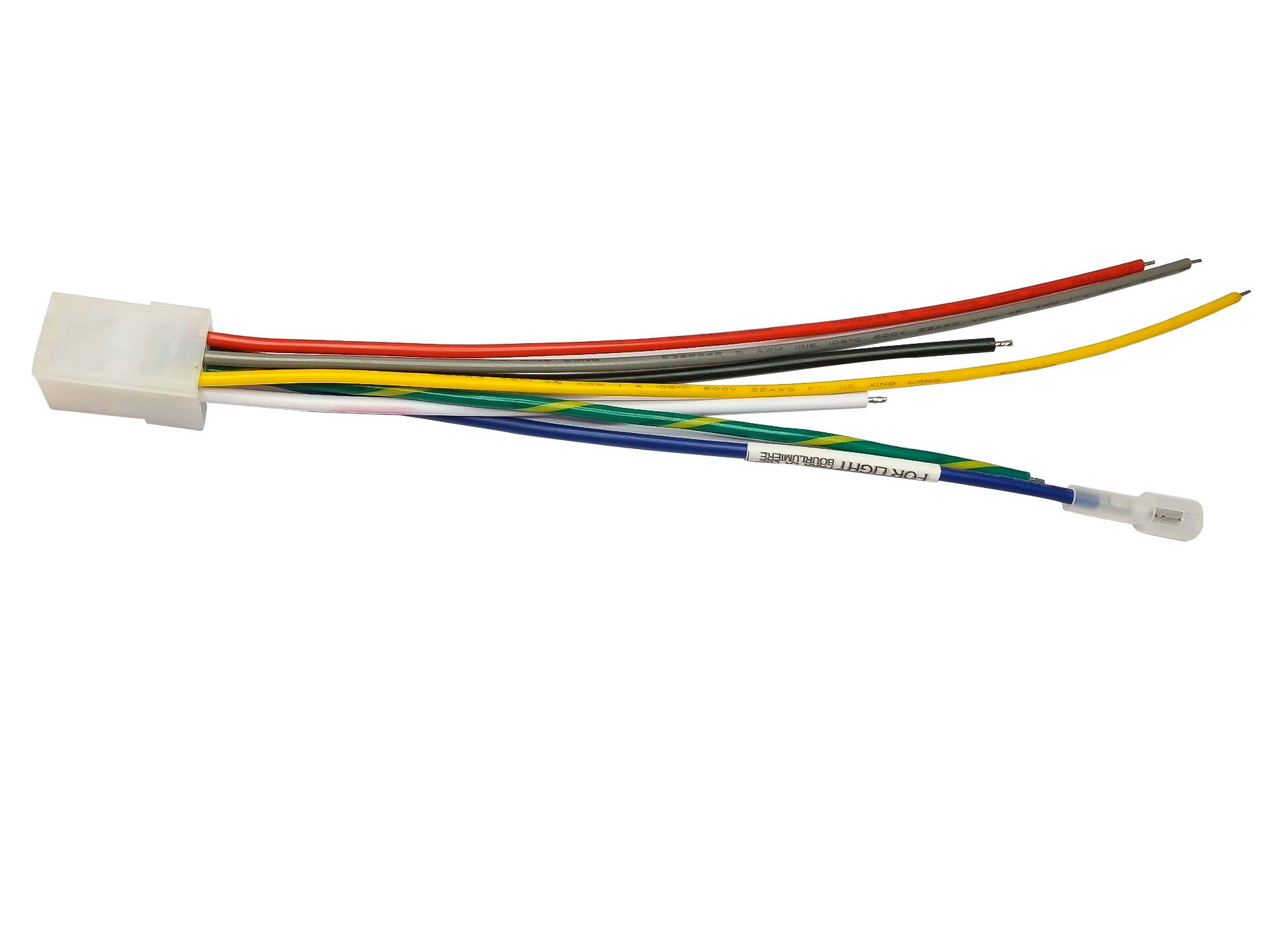

7. Riveted terminal: Conductor and plug terminal at riveted connection. Necessary equipment: terminal equipment. Technical requirements: The terminal shall not be deformed and must meet the requirements of tension, riveting height and width.

8. Product assembly:Assemble the plastic plug housing. Equipment requirements: electric screw driver. Technical requirements: the screw shall not expose the rubber surface and must meet the torque required by the product.

9. Conduction test:Conduct the harness continuity test with the instrument. Necessary equipment: continuity tester. Technical requirements: short circuit, open circuit, wiring error, poor contact, poor insulation and other phenomena are not allowed.

10. Packaging seal:The finished wire harness shall be packed in plastic bags and then put into cartons. Equipment required: sealing machine and packer. Technical requirements: the seal shall be flat, and the packing belt shall be close to the carton without falling off.

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd